| Applicable materials: | |

|---|---|

| Production speed: | |

| Max. unwind diameter: | |

| Max. width of raw material: | |

| Voltage: | |

| Availability: | |

| Quantity: | |

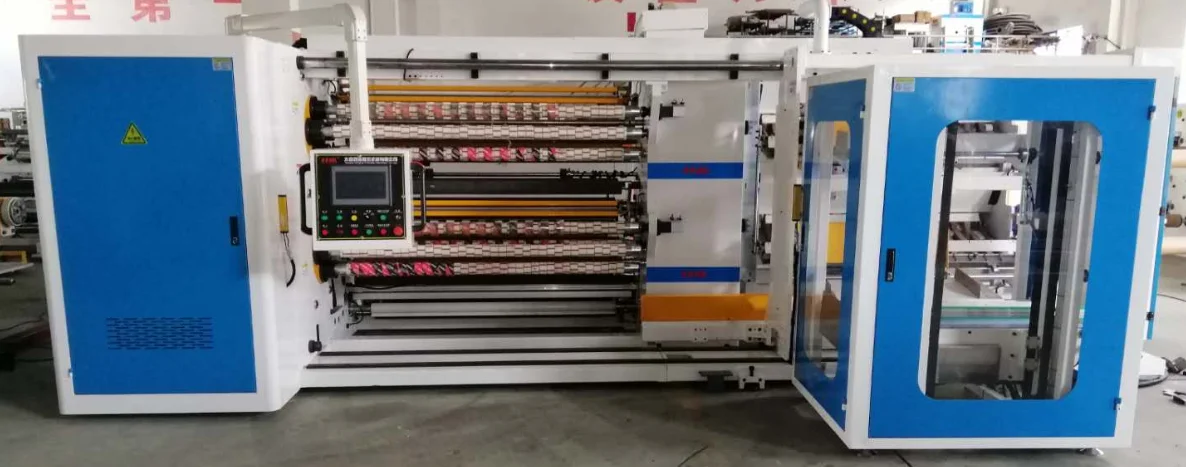

HH-1600

HHM

8477800000

1. Application

Suitable for highly efficient mass production of BOPP tape, masking tape, duct tape and etc.

2. Product description

Characteristic of HH-1600 High efficiency fully automatic BOPP tape masking tape and duct tape slitting machine.

Main features:

Unwind unit: automatic shaftless jumbo lift system, operation is fast and easy; noise hood reduces the noise and improves the quality and safety of the working environment; with pneumatic brake, constant tension control system and etc. Unwind unit: separate unwind stand, max. unwind diameter 1200mm, with more possibilities to install other devices.

Rewind unit - eight rewind shafts rotation and exchange: two shafts for rewinding, two for exchange, two for offloading, and two for core loading. Differential shafts or air shafts are optional to install.

Rewind drive unit: three-motor drive system: two rewind servo motors combined with the main one. Unwind & rewind tension isolation is done by the main motor, finished product tension is stable with nice appearance.

Automatic tabbing device: double-servo control label pulling and tabbing.

Automatic web cut-off device: smoothing press roller and tooth knife.

Slitting unit: razor blade or air score blade.

Offload and core load unit: integrated crane trolley for high speed positioning, offloading and core loading.

Core dropping mould unit: automatic core dropping and fast connection with size setting mould, performance is fast and reliable.

Electrical control unit: LCD touch panel is used for setting tension, length, etc. The control system adopts Siemens PLC to control movements with self-detection function, so error can be detected automatically. detected automatically.

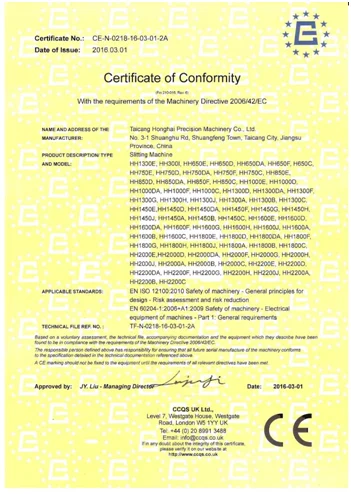

3. Certifications

4. Packing and shipping

Normally we use the seaworthy wooden cases to pack our machine.

If you have special requirements, please feel free to contact us.

5. Our service:

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

* Customize the machine according to your requirement.

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

* 1 year warranty

* Free share parts.

6. Contact us:

More details welcome to contact us, we would like to be your honest supplier in China.

And help you save the cost and make more profit in your market.

Mobile/ WeChat/ WhatsApp: +8615995593890

E-mail: hhmmach@vip.163.com

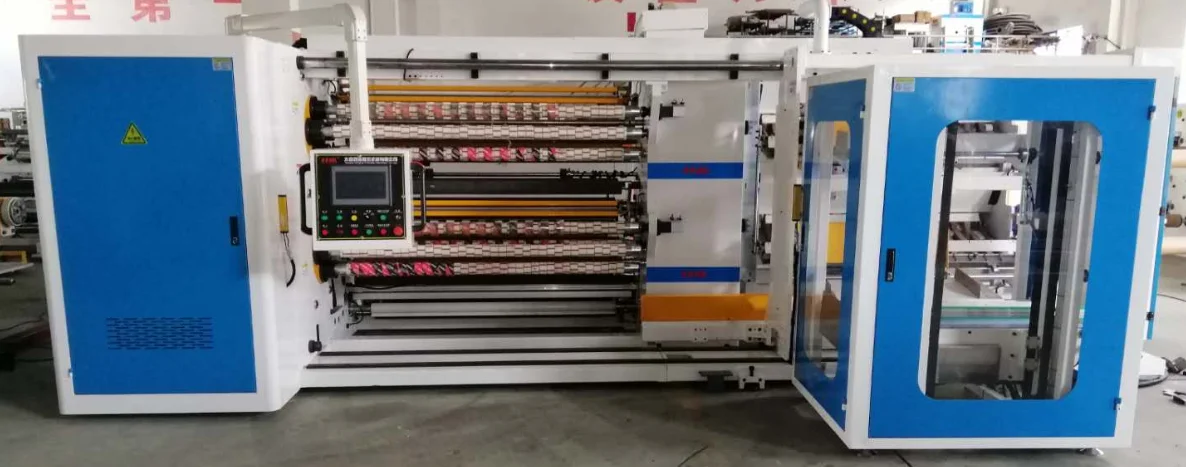

1. Application

Suitable for highly efficient mass production of BOPP tape, masking tape, duct tape and etc.

2. Product description

Characteristic of HH-1600 High efficiency fully automatic BOPP tape masking tape and duct tape slitting machine.

Main features:

Unwind unit: automatic shaftless jumbo lift system, operation is fast and easy; noise hood reduces the noise and improves the quality and safety of the working environment; with pneumatic brake, constant tension control system and etc. Unwind unit: separate unwind stand, max. unwind diameter 1200mm, with more possibilities to install other devices.

Rewind unit - eight rewind shafts rotation and exchange: two shafts for rewinding, two for exchange, two for offloading, and two for core loading. Differential shafts or air shafts are optional to install.

Rewind drive unit: three-motor drive system: two rewind servo motors combined with the main one. Unwind & rewind tension isolation is done by the main motor, finished product tension is stable with nice appearance.

Automatic tabbing device: double-servo control label pulling and tabbing.

Automatic web cut-off device: smoothing press roller and tooth knife.

Slitting unit: razor blade or air score blade.

Offload and core load unit: integrated crane trolley for high speed positioning, offloading and core loading.

Core dropping mould unit: automatic core dropping and fast connection with size setting mould, performance is fast and reliable.

Electrical control unit: LCD touch panel is used for setting tension, length, etc. The control system adopts Siemens PLC to control movements with self-detection function, so error can be detected automatically. detected automatically.

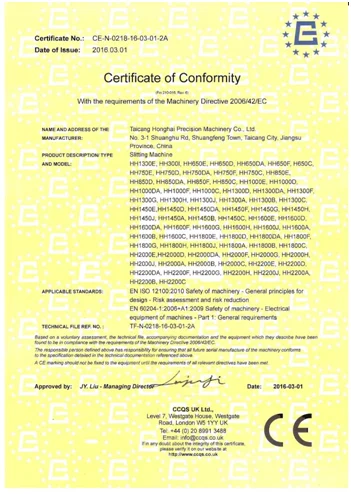

3. Certifications

4. Packing and shipping

Normally we use the seaworthy wooden cases to pack our machine.

If you have special requirements, please feel free to contact us.

5. Our service:

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

* Customize the machine according to your requirement.

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

* 1 year warranty

* Free share parts.

6. Contact us:

More details welcome to contact us, we would like to be your honest supplier in China.

And help you save the cost and make more profit in your market.

Mobile/ WeChat/ WhatsApp: +8615995593890

E-mail: hhmmach@vip.163.com